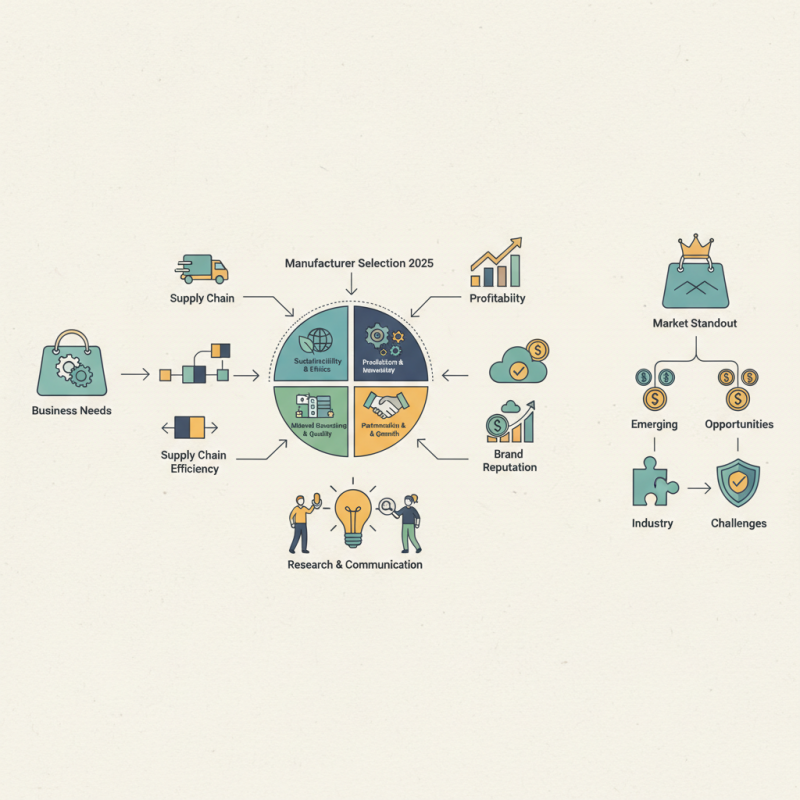

How to Choose the Right Bag Manufacturer for Your Business Needs in 2025

In the competitive landscape of 2025, selecting the right bag manufacturer is a critical decision for businesses aiming to stand out in their respective markets. As the demand for customized and sustainable products grows, companies must partner with manufacturers that not only align with their vision but also bring quality and innovation to the table. Renowned industry expert, Sarah Thompson, emphasizes this point: "Choosing the right bag manufacturer is more than just finding a supplier; it's about building a relationship that fosters creativity and long-term success."

A well-chosen bag manufacturer can significantly impact a business's reputation, supply chain efficiency, and, ultimately, its profitability. Factors such as production capabilities, material sourcing, and compliance with ethical standards have become increasingly vital. As businesses navigate these complexities, understanding the nuances of manufacturing processes and market trends is essential for making informed decisions. By aligning with a manufacturer that shares their values and understands their specific needs, companies can ensure that their products not only meet customer expectations but also contribute positively to their brand image.

Ultimately, the process of selecting a bag manufacturer extends far beyond cost considerations. It requires a strategic approach, involving thorough research and clear communication. In this dynamic environment, businesses that invest time in finding the right manufacturing partner will be well-positioned to capitalize on emerging opportunities and effectively respond to industry challenges.

Table of Contents

[Hide]

Identifying Business Needs: Assessing Your Bag Requirements for 2025

As businesses prepare for 2025, identifying specific bag requirements is crucial for enhancing operational efficiency and aligning with market trends. An analysis of consumer behavior indicates that 62% of customers prefer sustainable packaging options, reflecting a growing demand for eco-friendly materials in various sectors. This trend accentuates the importance of assessing whether potential bag manufacturers incorporate sustainable practices and materials in their production processes, which can significantly affect brand perception and customer loyalty.

Furthermore, with the global bags and luggage market expected to reach approximately $60 billion by 2025, understanding the particular needs of your business—such as functionality, aesthetics, and durability—becomes essential. Organizations should conduct a thorough analysis of their target demographic and intended use of the bags to ensure they select a manufacturer capable of meeting these requirements. Reports suggest that 54% of companies experiencing rapid growth have tailored their bag options to specific market segments, further demonstrating the necessity of precise bag specifications to capture valuable market share effectively.

Evaluating Manufacturer Capabilities: Quality, Capacity, and Technology Insights

When selecting a bag manufacturer for your business in 2025, a critical aspect to evaluate is their capabilities in quality, capacity, and technology. According to a recent report by IBISWorld, the global bag manufacturing industry is expected to grow steadily, with a projected revenue increase of 4.2% annually over the next five years. This growth signals an advanced level of competition among manufacturers, making it essential to scrutinize their quality control practices. A manufacturer should employ stringent quality assurance processes to ensure that the bags produced meet industry standards. Look for certifications such as ISO 9001, which indicates a commitment to quality management systems and continuous improvement.

Capacity plays a paramount role in ensuring that a manufacturer's operations align with your business demands. As highlighted by Technavio's research, a significant trend in the industry is the rise of automation in manufacturing processes, enhancing production capacity. Manufacturers employing advanced machinery and technologies demonstrate an ability to handle larger orders without compromising quality. It's important to assess whether a potential manufacturer has the infrastructure to scale production, as fluctuations in demand can occur.

Finally, consider their technological advancements, such as the use of eco-friendly materials and sustainable manufacturing practices. As sustainability continues to be a driving force within the industry, selecting a manufacturer that prioritizes innovation while minimizing environmental impact will better align with consumer expectations in the years to come.

Sustainability Trends: Choosing Eco-Friendly Bag Manufacturers

As sustainability becomes an increasingly pressing concern for consumers and businesses alike, choosing an eco-friendly bag manufacturer is more important than ever. In 2025, the demand for sustainable products is expected to rise significantly, prompting businesses to seek out manufacturers who prioritize environmentally responsible practices. This shift means that before selecting a bag manufacturer, businesses should evaluate their production processes, materials used, and overall impact on the environment. From biodegradable materials to energy-efficient manufacturing techniques, identifying a supplier committed to sustainability can help align your brand with consumer values.

Furthermore, transparency plays a crucial role in the selection of an eco-friendly bag manufacturer. Companies that openly share their sustainability initiatives, such as waste reduction strategies and carbon footprint assessments, demonstrate a genuine commitment to ethical practices. It is vital to engage with potential manufacturers about their sourcing of raw materials and their approach to labor practices as well. By prioritizing partnerships with companies that support fair trade and ethical labor practices, businesses not only contribute positively to the environment but also enhance their brand reputation in a marketplace increasingly focused on corporate social responsibility.

How to Choose the Right Bag Manufacturer for Your Business Needs in 2025 - Sustainability Trends: Choosing Eco-Friendly Bag Manufacturers

| Criteria | Description | Importance Level |

|---|---|---|

| Sustainability Practices | Use of eco-friendly materials and processes | High |

| Production Capacity | Ability to meet large order demands | Medium |

| Certifications | Certifications related to eco-friendliness | High |

| Flexibility | Willingness to customize products | Medium |

| Cost Competitiveness | Affordability compared to industry standards | Medium |

| Reputation | Past client reviews and success stories | High |

| Lead Time | Time taken to fulfill orders | Medium |

Comparative Pricing Strategies: Understanding Cost-Effectiveness in Bag Production

When selecting a bag manufacturer for your business needs in 2025, understanding the comparative pricing strategies is essential for maximizing cost-effectiveness in production. A recent report by the Global Market Insights reveals that the average cost of manufacturing a mid-range bag has increased by approximately 15% over the past three years, primarily due to rising raw material prices and labor costs. This inflation signifies the necessity for businesses to scrutinize pricing structures closely while ensuring product quality remains unaffected.

Tip: Always request detailed quotes from multiple manufacturers to understand the cost breakdown better. Look for manufacturers that provide transparent pricing models, which include material, production, and shipping costs. A thorough comparison can highlight potential hidden costs and save you significant money in the long run.

Additionally, manufacturers that leverage technology and automation in their production lines often present more competitive pricing options. According to a report by the International Data Corporation, firms that invest in automation may reduce operational costs by up to 30%. By identifying manufacturers that embrace technological advancements, businesses can benefit from both improved pricing and enhanced efficiency, leading to a more robust supply chain.

Tip: Evaluate potential manufacturers not just on price, but also on their production capacity and technological capabilities. This holistic approach will ensure you're getting the best value for your investment, while also securing a reliable partnership for future expansion.

Supplier Reliability: Analyzing Delivery Times and Support Services in 2025

When selecting a bag manufacturer in 2025, assessing supplier reliability is paramount for ensuring consistent production and fulfillment of business needs. A crucial aspect of this evaluation is the analysis of delivery times. Timely deliveries not only impact inventory management but also influence customer satisfaction. Therefore, potential manufacturers should provide clear timelines and demonstrate a track record of meeting or exceeding those deadlines. It's advisable to inquire about their lead times for both samples and bulk orders, assessing their ability to accommodate urgent requests when necessary.

In addition to delivery times, the quality of support services offered by a manufacturer plays a significant role in establishing a reliable partnership. A responsive customer service team that is available to address concerns and answer questions can enhance communication and streamline the manufacturing process. Effective support services also include regular updates on order status and proactive problem-solving during unforeseen issues. Evaluating these factors will help businesses choose a manufacturer that is not only dependable in their delivery schedules but also committed to fostering a collaborative and supportive business relationship.

Related Posts

-

Unlocking Quality: Key Criteria for Selecting the Best Bag Manufacturer for Global Sourcing

-

How to Choose the Right Bag Supplier for Your Business Needs

-

Discover Unmatched Quality of Eco Bags from China Leading Factories Trusted by Global Buyers

-

Exploring the Future of Hessian Bags: Insights from China’s 138th Import and Export Fair 2025

-

Why Choose a Jute Tote: The Sustainable and Stylish Bag for Every Occasion

-

Global Sourcing of Best Hessian Bags Made in China A testament to Quality and Innovation

We are the most reliable and proficient jute goods manufacturer & supplier that helps businesses or individuals with various exportable agricultural commodities biz and jute goods by shipping them worldwide. Our right-time service ensures that whatever color and size of jute product you need, we can make it happen anytime and anywhere! Let’s keep our earth safer to live in!

Important link

Address

Bangladesh Address:

Fair Plaza (9th Floor), Plot : 3C, Section : 01, Mirpur, Dhaka:1216

UK Office:

242 Manor Road, Droylsden, Manchester, M43 6JD, United Kingdom.

Let's Talk

We are the most reliable and proficient jute goods manufacturer & supplier that helps businesses or individuals with various exportable agricultural commodities biz and jute goods by shipping them worldwide. Our right-time service ensures that whatever color and size of jute product you need, we can make it happen anytime and anywhere! Let’s keep our earth safer to live in!

Get Started

Let's Talk

Address

Bangladesh Address:

Fair Plaza (9th Floor), Plot : 3C, Section : 01, Mirpur, Dhaka:1216

UK Office:

242 Manor Road, Droylsden, Manchester, M43 6JD, United Kingdom.