Burlap bags, commonly known as gunny sacks or hessian bags, are essential to global trade, agriculture, packaging, and sustainable fashion. These bags are made from jute, a fast-growing natural fiber with a low environmental impact. The market demand for burlap bags is rising steadily due to increased awareness of plastic pollution and the global shift toward biodegradable packaging alternatives.

The jute industry employs over 5 million people in countries such as Bangladesh and India, accounting for more than 90% of the global jute supply. Burlap’s versatility makes it suitable for packaging grains, coffee, cocoa, promotional items, and even decorative products. Grades, weave types, and treatments of burlap fabric vary based on the end-use, from rugged agricultural sacks to soft, blended lifestyle totes.

What Is a Burlap Bag and Why Is It Widely Used?

A burlap bag is a breathable, reusable sack made from woven jute or hessian fabric, used globally for storing, packaging, and transporting goods.

These bags are praised for their natural ventilation, tensile strength, and eco-friendliness. Unlike plastic alternatives, burlap decomposes in under a year without releasing toxins, making it a key component in sustainable packaging. Industries such as agriculture, logistics, and retail rely heavily on burlap bags due to their ability to protect contents while minimizing environmental harm.

Jute, the primary raw material, is primarily cultivated in India and Bangladesh, where favorable climate conditions support high-fiber yields. According to the International Jute Study Group (IJSG), global jute production was estimated to be over 3.5 million metric tons in recent years, with the majority used in burlap manufacturing. The bags are available in various forms, from large sacks for commodities to small pouches for gifts or branding, each serving specific commercial needs.

Natural or Pure Burlap (Jute Burlap)

Natural burlap is the most basic and widely available type of burlap fabric. It is made from untreated, coarse jute fibers that are spun and woven into a breathable, biodegradable fabric. Often referred to as “raw jute” or “gunny cloth,” this version retains the original tan-brown color of jute and is characterized by its rugged texture.

Specifications: Typically include GSM (grams per square meter), ranging from 275 to 340, with a loose weave that is ideal for storing grains, pulses, or firewood. It allows for airflow and moisture escape, which helps prevent spoilage. Natural burlap bags are commonly used in agriculture, construction, and erosion control because they are low-cost and easily decompose in soil.

Fine Burlap

Fine burlap is a smoother, tightly woven fabric variant made from high-quality jute yarn. This type of burlap is processed with greater attention to uniformity, resulting in a more refined finish and softer hand feel.

What it is used for: Fine burlap is ideal for high-touch applications such as interior décor, crafting, floral arrangements, and luxury gift packaging. Because of its aesthetic appeal and reduced shedding, it is preferred for premium use cases.

Specifications include higher thread counts, finer gauge yarns, and GSM values that are often on the lower side (around 220–280) due to tighter weaving.

Coarse Burlap

This type of burlap features a loose weave with thick, rough yarns, resulting in a strong, heavyweight fabric. Coarse burlap is more rigid and has a scratchier surface compared to fine burlap.

Use cases include potato sacks, firewood carriers, concrete curing blankets, and tree root protection. The roughness makes it suitable for non-consumer, industrial uses where visual quality is not a priority.

Specifications typically start at 320 GSM and increase, with open weaves allowing for fast drying and ventilation.

Laminated Burlap

Laminated burlap is burlap fabric bonded to a thin film of polyethylene or resin to make it water-resistant and dust-proof. The lamination adds a barrier layer that prevents fiber shedding and protects against mold, making it suitable for damp environments.

Applications range from fertilizer packaging and chemical transport to food-grade sacks in humid climates. Lamination also enhances printability, making it suitable for branding purposes.

Specifications vary by lamination thickness, but fabric GSM ranges from 300 to 350, often with a laminated film of 30–50 microns.

Waxed Jute

Waxed burlap is treated with paraffin or natural waxes to enhance its durability and resistance to outdoor elements. The wax adds a glossy finish and enhances the fabric’s ability to repel water.

What it’s used for: It is Often used in tool wraps, field kits, picnic mats, outdoor retail packaging, and protective sheaths. The wax not only preserves the bag’s integrity but also adds a unique texture that appeals to consumers.

Specifications depend on the amount of wax used, but waxed burlap often starts from a base of 280–320 GSM and is treated post-weave.

Blended Burlap

Blended burlap is a fabric composed of jute mixed with other fibers such as cotton, polyester, or viscose. The blending process improves the flexibility, softness, and sometimes tear resistance of the final product.

Use cases include eco-friendly fashion totes, home accessories, and decorative bags where touch and finish are crucial. Brands seeking more refined products with a rustic look often prefer blended burlap.

Specifications depend on the fiber blend ratio. Typical compositions include 60% jute and 40% cotton, with a GSM (Grams per Square Meter) range of 250 to 320. These bags often support complex stitching and high-quality screen printing.

Dyed Burlap

Dyed burlap is processed with natural or synthetic dyes to achieve specific colors for branding, decoration, or thematic events. After weaving, the fabric is treated to absorb and lock in color.

Where it’s used: Frequently seen in weddings, retail stores, corporate gifting, or seasonal product displays, the ability to match corporate branding makes dyed burlap a staple in promotional campaigns.

Specifications are similar to those of untreated burlap (280–340 GSM), but additional care is required to ensure dye fastness and non-bleeding properties, especially if the bag will come into contact with food or absorb moisture.

Hydrocarbon-Free Burlap

Hydrocarbon-free burlap is a chemically purified version of natural burlap that removes any trace of mineral oils or petrochemical residues left from jute batching oil during processing.

Purpose: This treatment makes the fabric odorless and safer for direct food contact, nursery use, and export to countries with strict chemical residue limits. It is a common requirement in organic farming and seed transportation.

Specifications match those of natural burlap in terms of weave and GSM, but the hydrocarbon removal process adds value and ensures certification compliance (such as GOTS or OEKO-TEX).

Types of Burlap Bags by Shape, Size, and Closure Style

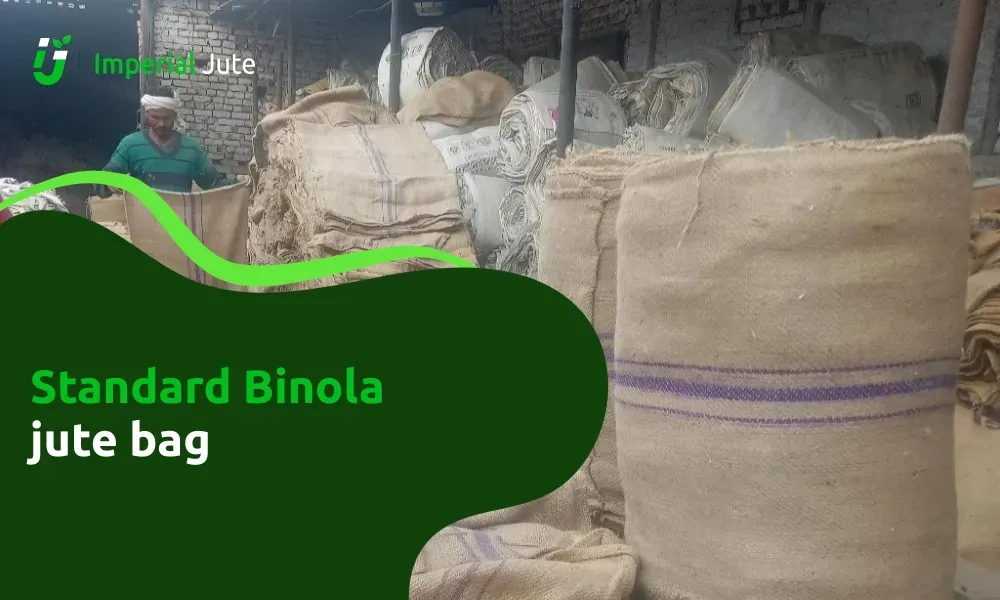

Sack Bags (Gunny Bags)

Sack bags, also known as gunny bags, are large-capacity containers commonly used in agriculture and the shipping of commodities. These bags are typically cylindrical or rectangular, featuring either an open mouth or stitched bottom.

What they are: Made from medium to coarse burlap, these bags are breathable and cost-effective, making them ideal for bulk transport of grains, coffee beans, potatoes, peanuts, or charcoal.

Specifications often include dimensions such as 22″ ×36″ or 24″ ×40″, with a fabric weight ranging from 275 to 340 gsm. The mouth may be hemmed for closure or left open for easy filling. Their capacity ranges from 25 kg to 100 kg, depending on the product density.

Tote Bags

Tote bags are flat-bottomed or gusseted bags with handles, designed for carrying by hand or over the shoulder. They are used in various retail, event, and lifestyle applications.

Use case: Burlap totes are increasingly favored as alternatives to plastic bags due to their reusability and rustic visual appeal. They’re popular in farmers’ markets, fashion lines, eco-conscious campaigns, and brand merchandising.

Specifications range from small sizes (10″ × 12″) to large formats (14″ × 18″) with longer jute or cotton-wrapped handles. These are often made from blended or dyed burlap in the 220–280 GSM range for a better finish and flexibility.

Drawstring Bags

These are lightweight, pouch-style bags that use a jute, cotton, or synthetic string to cinch and close the bag’s opening.

What they are used for: Ideal for promotional giveaways, gift packaging, or storing small items like herbs, soaps, or coins. These bags are easy to produce, reusable, and offer low-cost branding potential.

Specifications vary widely from 4″×6″ mini pouches to 12″×16″ medium formats. Fabric GSM typically ranges from 200 to 280, depending on size and intended reuse.

Wine Bags

Wine bags are slender, tubular burlap carriers designed to hold wine or olive oil bottles, often with dividers or padding for multiple units.

Purpose: Used in wineries, boutique stores, or as upscale corporate gifts, these bags are typically decorative and often feature ribbons, tags, or custom prints.

Specifications generally fit standard 750ml bottles, with dimensions around 6″ ×14″. GSM ranges from 220 to 260, and they often feature laminated inner linings to prevent seepage.

Backpacks

Burlap backpacks merge sustainable fashion with practicality. They are reinforced with cotton or canvas linings and come with straps, zippers, and pockets.

Use cases: Often seen in eco-branding campaigns, music festivals, or educational giveaways, these bags appeal to youth markets and NGOs.

Specifications include dimensions like 12″×16″×5″, with higher GSM (300+) and additional stitching support. Many are made from blended burlap for softness and strength.

Pouch Bags

Pouch bags are small-format sacks used for jewelry, wedding favors, soaps, or loose-leaf teas. They may come with Velcro, snaps, or drawstring closures.

Why they’re used: Their tactile quality and natural look make them popular for gift packaging or specialty retail.

Specifications include sizes such as 3″ ×4″, 5″ ×7″, or 6″ ×8″, typically with a GSM of 180–240 g/m². These bags are often dyed or screen-printed for custom branding.

Grow Bags

Grow bags are specially designed for planting vegetables, herbs, or flowers in urban gardening and nursery environments. Burlap’s breathability supports root development and water drainage.

Application: Used by organic farms, home gardeners, and hydroponic setups, these bags reduce transplant shock because they can be planted directly in the soil.

Specifications range from 10 liters to 50 liters in capacity, often lined with biodegradable material. GSM varies from 280 to 320, depending on the load-bearing requirement.

Types of Burlap Bags by Purpose and Application

Agricultural Sacks

Agricultural sacks are heavy-duty burlap bags used primarily for transporting and storing produce, such as potatoes, onions, cocoa, coffee beans, and grains. These sacks are chosen for their breathability, allowing harvested items to stay fresh longer by preventing moisture buildup.

What they are: These are large-sized, coarse burlap bags designed for rugged use. They allow for air circulation, reducing spoilage and mold, especially in humid climates.

Specifications typically include capacities of 25 kg, 50 kg, or 100 kg, with dimensions of approximately 24″ ×40″. The fabric normally has a GSM of 300–340 and is either untreated or hydrocarbon-free, depending on its intended use for food products. Some versions come with double stitching for added durability.

Sandbags

Sandbags are used for flood control, erosion prevention, and military or civil defense purposes. Burlap sandbags are favored for their natural decomposition in environmental use cases.

What they are: Compact, fillable bags made from coarse, untreated burlap designed to hold weighty materials like sand, soil, or gravel.

Specifications include sizes like 14″×26″ or 18″×30″, with a GSM of 275–320. These bags are used in layers or stacked to build barriers, and their porous nature allows slow water drainage, reducing hydrostatic pressure. For short-term use, burlap is preferred over synthetic alternatives due to biodegradability.

Gift and Favor Bags

Gift and favor bags are small, often decorative bags made of burlap used for packaging party favors, promotional items, or personal gifts. These bags are typically custom-printed or accessorized.

Use cases Include Weddings, birthdays, baby showers, product launches, and cultural festivals. The rustic texture of burlap adds charm and a sense of sustainability to the presentation.

Specifications are usually 4″×6″, 5″×7″, or 6″×9″, with a GSM of 200–250. These bags are commonly dyed, stamped, or embellished with lace, twine, or tags. Drawstring closures are the most common, but zippers or button flaps are also used in premium versions.

Promotional Bags

Promotional burlap bags are custom-printed totes, pouches, or wine bags distributed by brands at expos, trade shows, or retail stores. They serve both functional and advertising purposes.

What they are: Branded carry bags made from fine or blended burlap that align with eco-conscious branding strategies. Their surface accommodates a high-quality screen or digital printing.

Specifications range based on size and function—commonly 12″×15″ totes or 6″×13″ wine sleeves. GSM ranges from 220 to 280, with or without lamination. Brands often add pockets, custom handles, or interior linings for a premium feel.

Décor Bags

Décor bags are used as aesthetic accessories in interior design, retail displays, or seasonal decoration. These burlap bags may be filled with faux goods, used as planters, or integrated into rustic setups.

Where they’re used: Farmhouse-style homes, cafés, wedding venues, or retail store themes. The texture of burlap complements wood, metal, and glass elements, making it a staple in rustic or industrial design.

Specifications vary widely, both in shape and treatment. Typical dimensions include 10″×10″ or larger for indoor planters, with GSM from 200 to 300. Often dyed, screen printed, or accessorized for visual enhancement.

Storage Bags

Storage bags made from burlap offer a breathable alternative to plastic containers for items like seasonal clothes, toys, or craft supplies. They help prevent mold, odor, and mildew in stored items.

What they are: Large or medium-format bags with or without closures, designed to store non-perishable goods in homes, workshops, or studios.

Specifications include 16″×20″ or 18″×24″ sizes with a GSM of 250-300. Some bags include a laminated inner lining, a cotton drawstring, or reinforced stitching for added durability in heavy use. These bags are often used in zero-waste households and sustainable retail environments.

How Burlap Bags Are Manufactured: From Jute Fiber to Final Packaging

Burlap bag manufacturing is a multi-stage process that begins with the cultivation of raw jute and culminates in finished bags ready for industrial or consumer use. Each step from harvesting to stitching affects the durability, texture, and cost of the final product.

Sourcing Raw Jute Fibers

Jute is primarily grown in warm, humid regions, such as Bangladesh and eastern India, where seasonal floods naturally irrigate the soil. Once mature, the jute plant is harvested and subjected to retting a microbial process in which the stalks are soaked in water to loosen the fibers.

After retting, fibers are stripped, sun-dried, and bundled for transport to mills. According to the Food and Agriculture Organization (FAO), India and Bangladesh account for over 90% of global jute production, supplying raw materials to most burlap manufacturers worldwide.

Spinning and Yarn Preparation

At the mill, raw jute is sorted by grade, then passed through a softening process using batching oil. Fibers are then carded (combed), spun into yarn, and wound onto bobbins or cones. The thickness of the yarn determines the fabric’s weight (GSM) and texture—fine yarn is used for craft and décor bags, while coarser yarn is used for sacks and sandbags.

Weaving the Fabric

Weaving is done on either power looms or handlooms, depending on the production scale and regional requirements. The weave density, usually in plain or twill patterns, defines the strength and breathability of the burlap.

Finished rolls are categorized by width (typically 40–60 inches) and length (in meters or yards), ready for further processing. At this stage, dyed, laminated, or hydrocarbon-free treatments may also be applied.

Cutting and Stitching

Fabric rolls are cut into panels based on the desired bag size. High-speed industrial machines stitch the sides, bottoms, and handles if required. Common stitch types include lockstitch or chain stitch, depending on load capacity. Additional steps may include inserting drawstrings, zippers, or eyelets.

Branding, labeling, or printing (on screen or digitally) is also done here. In some cases, bags are heat-sealed if lamination is used.

Global Sourcing and Bulk Procurement Insights

Burlap bag sourcing at scale involves identifying reliable suppliers, understanding export hubs, and evaluating cost structures based on material quality, compliance, and customization. Global demand is concentrated in sectors such as agriculture, construction, and eco-packaging, where procurement officers must align environmental compliance with budget and lead times.

Key Export Markets: India, Bangladesh, and China

India and Bangladesh dominate global jute bag exports due to their climatic suitability for jute cultivation and vertically integrated manufacturing ecosystems. Bangladesh, often considered the world’s jute capital, supplies over 60% of global demand, with Dhaka and Khulna as major production zones. Indian states like West Bengal and Assam also produce large volumes, benefiting from modernized jute mills and government incentives.

China, while not a primary jute grower, plays a role in sourcing raw jute from South Asia and finishing it into value-added burlap products such as totes, decorative pouches, and laminated sacks. Chinese factories are known for flexible customization and fast turnaround times, particularly for private-label or branded items.

Export reliability is often evaluated based on production capacity, ethical practices, and shipment handling. Many importers rely on third-party audits or certifications before finalizing sourcing contracts.

Minimum Order Quantities (MOQ) and Lead Times

The MOQ varies depending on the type of burlap bag and the supplier’s location. For basic gunny sacks, MOQs typically start at 1,000 to 5,000 units. For customized or laminated bags, suppliers may require 2,000 to 10,000 units due to setup and printing costs.

Lead times for bulk orders range from 15 to 45 days, depending on bag complexity, factory load, and shipping route. Port congestion and raw fiber shortages (especially during monsoon seasons in South Asia) can affect timelines. Buyers often schedule staggered shipments or buffer inventory for critical cycles.

Flexible contracts with split deliveries, seasonal pricing, and freight-on-board (FOB) or cost, insurance, and freight (CIF) options are standard in high-volume B2B procurement. Advanced planning is advised when sourcing for export seasons or events to avoid customs delays and inventory gaps.

Where to Buy Burlap Bags (Retail and Wholesale Options)

Burlap bags are available through a wide range of channels, from local suppliers to global e-commerce and B2B platforms. The choice of platform depends on quantity, customization needs, and delivery timelines.

Retail buyers can source ready-made burlap bags from platforms like Amazon, Etsy, and Walmart, which offer a variety of decorative, gifting, and reusable totes in low volumes. These options suit personal, craft, or small business use.

Wholesale buyers and importers often turn to platforms like Alibaba, IndiaMART, TradeIndia, GlobalSources, or Made-in-China to engage directly with manufacturers or bulk suppliers. These platforms allow for RFQs (Request for Quotes), MOQs negotiation, and quality verification.

For local sourcing, packaging distributors or agricultural supply stores stock standard sack formats and drawstring bags in bulk. Buyers seeking region-specific compliance (such as EU eco-labels or USDA organic packaging) typically work with sourcing agents who audit factories and handle logistics.

Frequently Asked Questions (FAQs) About Burlap Bags

What is a burlap bag?

A burlap bag is a woven sack made from natural jute fibers, used for packaging, storing, and transporting goods such as grains, produce, gifts, or promotional materials.

Where can you buy burlap bags?

Burlap bags can be purchased from local packaging suppliers, wholesale markets, online retail platforms like Amazon or Etsy, and B2B directories such as Alibaba, IndiaMART, or directly from jute mills.

How to make a burlap bag?

To make a simple burlap bag, cut a piece of jute fabric to your desired size, fold it, and stitch the sides. Add closures like drawstrings or handles using cotton cords or webbing for a functional finish.

How to personalize burlap bags?

Personalization can be done through screen printing, block stamping, embroidery, or dyeing. Many suppliers offer logo printing, tag attachment, or colored stitching for branding or gifting purposes.

Final Thoughts

Burlap bags combine eco-friendliness with durability, making them a vital component of both global supply chains and sustainable consumer trends. Whether used for transporting commodities or branding retail items, they offer long-term value through biodegradability, reusability, and regional availability.

For businesses focused on ethical sourcing and cost control, understanding fabric types, manufacturing origins, and procurement logistics is key to making informed and scalable purchasing decisions.