As the demand for biodegradable alternatives rises globally, jute twine and rope have emerged as leading natural fiber solutions. Known for their durability, strength, and eco-friendly nature, these products are reshaping sectors like agriculture, packaging, and interior décor.

Unlike synthetic alternatives, jute twine and rope are not only compostable but also renewable. With countries enforcing stricter plastic regulations, industries are turning to jute to meet both functional and environmental needs.

According to a report by Grand View Research, the global jute market is expected to surpass USD 6.8 billion by 2027. Much of this growth is fueled by the increasing popularity of jute-based packaging and sustainable craft products, especially in Europe, the Middle East, and North America.

This article explores what makes jute twine and rope unique, their uses across industries, their biodegradability, and why global demand for jute products continues to rise.

Natural Jute Fibre: Origin and Manufacturing Process

Jute is primarily grown in Bangladesh and India, which together produce over 90% of the world’s jute supply. The plant grows best in warm, humid climates with adequate rainfall and matures within 4 to 6 months.

The jute manufacturing process begins with the retting of the harvested stalks in water, where natural microbial action helps loosen the fibers. Once softened, fibers are stripped, washed, and dried. These raw fibers are then combed and spun into yarn using traditional or mechanized techniques.

This yarn is used to make both twine and rope, with the process adjusted depending on the thickness, texture, and tensile strength required. Importantly, jute processing uses no harmful chemicals, making the entire chain eco-friendly and low-impact. Modern jute mills, especially those exporting to global markets, follow quality controls like ISO certifications and lab-tested tensile grades to meet international standards.

Is Twine Biodegradable? Comparing Jute to Synthetic Twine

Not all twine is biodegradable. While jute twine breaks down naturally, most synthetic alternatives like nylon, polypropylene, or polyester can persist in the environment for decades.

Synthetic twines are made from petrochemicals. When disposed of, they often release microplastics that contaminate water sources, harm wildlife, and contribute to long-term pollution. According to a 2022 UNEP study, synthetic microfibers make up nearly 35% of the plastics polluting global oceans.

In contrast, jute twine is made entirely from lignocellulosic biomass. Its biodegradation rate can range between 2 to 6 months under composting conditions, depending on the thickness and environmental exposure. This makes it ideal for industries like agriculture and landscaping, where short-term durability is needed but long-term residue is undesirable.

Global shifts in environmental policy are also accelerating the shift to biodegradable twines. For instance, the European Union’s Green Deal encourages the phasing out of plastic packaging and synthetic cords in favor of compostable alternatives. Jute twine aligns perfectly with these goals.

Is Twine Compostable? What Happens After Disposal

Yes, jute twine is fully compostable and leaves no harmful residue. When placed in compost bins or soil, it decomposes into carbon dioxide, water, and nutrient-rich biomass.

The composting timeline varies. Thin jute twine used in packaging may begin breaking down in 4 to 8 weeks in a hot compost system. Thicker ropes may take a bit longer, especially in cooler or drier climates. However, the end result remains the same a return of organic matter to the earth.

Because no toxic adhesives or plastic fillers are used in natural jute twine, it is safe for home composting, industrial compost systems, and even municipal green waste programs. This is especially valuable in urban gardening and organic farming, where soil purity is critical.

Moreover, some jute products used in agriculture are designed to be plowed directly into the soil after use. These biodegradable ropes not only reduce waste but also improve soil structure and microbial activity.

Most Common Uses of Jute Twine and Rope

Jute twine and rope are used across a wide range of industries—from agriculture to retail and interior design. Their strength, flexibility, and eco-friendliness make them ideal for both functional and decorative applications.

Whether used to tie hay bales, decorate wedding venues, or wrap artisan packaging, jute continues to replace plastic-based alternatives in numerous sectors. The growing demand is fueled by sustainability trends, consumer preference for natural aesthetics, and compliance with eco-regulations.

Natural Fiber Twine for Gardening, Hay Bales & Landscaping

In agriculture and landscaping, jute twine plays a critical role in bundling, tying, and supporting plant growth. It is biodegradable, which means farmers and gardeners can leave it in the soil without worrying about long-term waste.

Gardeners use jute twine to tie tomato plants, train vines, and create trellises. Because it decomposes naturally, it won’t strangle plants or pollute the soil. Landscapers often prefer jute rope to secure erosion control mats, stabilize young trees, or hold together straw wattles used in slope management.

In farming, especially hay baling, jute twine is used to bundle straw and hay. While synthetic baling twine is more common in large-scale mechanized operations, many small and organic farms choose jute due to its compostability and environmental safety. A study published by the Indian Council of Agricultural Research found that jute baling twine resulted in no adverse soil impact even after repeated use and decomposition.

String for Cake Boxes, Gift Wrapping & Product Packaging

Jute twine is a popular choice in the packaging industry, especially for businesses that want to reflect eco-conscious branding. Bakeries, artisanal product sellers, and eco-retailers use jute to tie cake boxes, wrap product tags, and decorate packaging.

Its natural, rustic appearance complements kraft paper and recycled packaging materials. This not only enhances product presentation but also reinforces a brand’s sustainability message. According to Nielsen’s Global Sustainability Report, 66% of consumers are willing to pay more for products from brands committed to positive environmental impact. Jute packaging helps brands visually communicate that value.

In eCommerce and retail packaging, thin jute twine is also used as an alternative to plastic twist ties or poly ribbons. It’s lightweight, strong, and doesn’t interfere with the recyclability of the main packaging.

Jute Rope Craft Ideas: Macramé, Décor, and More

The demand for jute rope in the home décor and crafting industry has grown significantly in recent years. Its natural color, texture, and flexibility make it perfect for handmade projects, macramé wall hangings, rustic lighting, and furniture accents.

Interior designers increasingly use thick jute ropes for nautical or bohemian-themed spaces. DIY hobbyists use them for making planters, coasters, lamp covers, and even wedding centerpieces. According to Etsy marketplace data, searches for “jute rope crafts” and “macramé rope” have increased by over 40% year-over-year since 2021.

Craft exporters from countries like Bangladesh and India cater to this niche by offering pre-dyed, combed, or waxed jute ropes tailored for decorative use. Unlike industrial-grade ropes, these are often softer and free of dust or impurities, making them suitable for direct handling and indoor display.

Why Jute Twine is in High Demand Globally

Global demand for jute twine and rope is rising sharply due to increasing environmental awareness and policy-driven shifts away from plastic-based materials. From packaging and agriculture to crafts and logistics, industries are adopting jute as a reliable, sustainable alternative.

This shift is not only driven by ethical concerns but also by legislation, brand positioning, and evolving consumer preferences. The versatility and biodegradability of jute make it a material of choice for exporters and importers worldwide.

Impact of Plastic Bans and Eco Regulations on Demand

The growing wave of plastic bans across the globe is directly influencing the adoption of natural alternatives like jute. Governments are pushing legislation that restricts single-use plastics, leading industries to explore safer and more compliant materials.

For example, the European Union’s Single-Use Plastics Directive and similar policies in the USA, Canada, and India have banned or heavily taxed plastic packaging and synthetic cords. As a result, manufacturers and retailers are transitioning to jute twine for packaging, product bundling, and labeling. This material meets compliance needs while supporting sustainable brand messaging.

A 2023 report by McKinsey & Company highlighted that nearly 70% of surveyed businesses in consumer goods and agriculture are actively shifting to compostable packaging to meet environmental targets. Jute fits these targets well because it offers durability, cost-effectiveness, and full biodegradability without needing industrial composting.

The food and farming sectors are especially affected by these policies. Synthetic baling twine, once the standard, now faces scrutiny for leaving long-lasting plastic residue in fields. As a result, biodegradable options like jute are gaining favor in both small-scale organic farms and large-scale commercial agriculture.

Key Markets Driving Growth: USA, EU, Middle East

Jute twine and rope exports are surging in regions with strong sustainability mandates and growing demand for eco-conscious products. Three of the biggest markets driving this growth are the United States, the European Union, and the Middle East.

The USA has become one of the top importers of jute-based products, especially through eco-friendly retail chains, organic farms, and DIY consumer markets. The rise of small businesses on platforms like Etsy and Amazon Handmade has increased the demand for natural packaging and craft materials, where jute twine plays a prominent role.

In the EU, demand is even stronger, supported by strict environmental regulations and incentives for sustainable procurement. Germany, France, the Netherlands, and the Nordics are among the largest importers. European retailers use jute extensively in packaging, textile applications, and eco-design products.

The Middle East, especially the UAE and Saudi Arabia, is seeing a rising demand for jute rope in logistics, farming, and retail sectors. The shift aligns with regional sustainability goals, such as Saudi Vision 2030 and the UAE’s national sustainability strategy, both of which aim to reduce plastic use and promote natural alternatives.

Bangladesh, as the world’s leading exporter of jute, benefits significantly from this demand. Exporters in the country are expanding their offerings with customized twine and rope grades to meet B2B specifications in each of these regions.

Exporting Jute Twine and Rope: What Buyers Need to Know

Exporting jute twine and rope involves more than just manufacturing the product. International buyers require consistency, compliance, customization, and proven quality. Exporters must meet country-specific regulations and industry expectations while delivering products that suit each use case—from agriculture to artisan retail.

Understanding exporter capabilities, product variations, and certification standards is essential for importers to ensure they receive eco-friendly, high-performance jute materials.

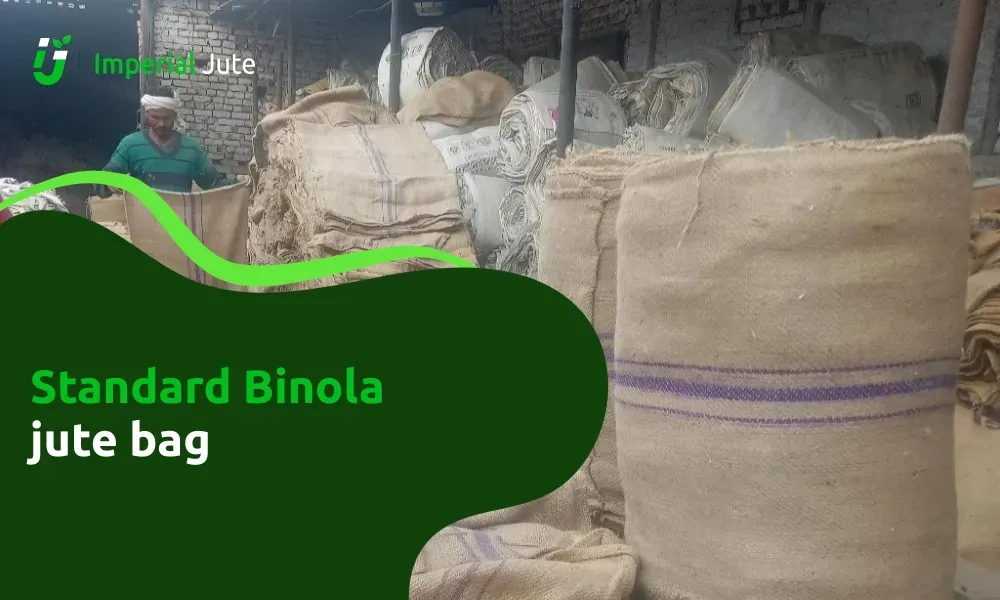

Jute Twine Rope Tying Exporter: What They Offer

Exporters of jute tying rope typically serve industries like agriculture, logistics, and packaging. These ropes are used to tie sacks, bundle crops, and secure loads in transport and storage.

A good tying rope exporter offers multiple thickness grades, twist levels (single-ply, double-ply), and packaging options (spools, coils, or hanks) to match the needs of their buyers. They also customize based on tensile strength, moisture resistance, and color if needed.

Leading exporters, especially from Bangladesh and India, have upgraded machinery and compliance processes to meet global specifications. Many now offer OEM services, eco-label printing, and biodegradable certifications to meet client-specific sustainability standards. Buyers from the US and EU often seek eco-certification (like GOTS or USDA BioPreferred) as part of their sourcing criteria.

What is Jute Twine and Rope?

Jute twine and rope are strong cords made from the long, soft, and shiny fibers of the jute plant. They are biodegradable, eco-friendly, and widely used across industries for their strength and natural texture.

Jute twine is typically thin and flexible, making it ideal for tying, binding, and crafting. It is widely used in gardening, retail packaging, and decorative applications. Jute rope, on the other hand, is thicker and more robust, often used for heavier-duty tasks in agriculture, shipping, and home décor.

Both products are known for their coarse texture, earthy appearance, and sustainable lifecycle—from farming to disposal. They represent one of the most eco-responsible alternatives to plastic and synthetic fibers currently available.

What is the Difference Between Jute Twine and Jute Rope?

Jute twine and rope differ primarily in thickness, tensile strength, and application. Twine is generally made with finer yarn and is used for lightweight tying, while rope is spun with thicker strands and designed for more robust usage.

Twine typically measures between 1 to 4 mm in diameter and is spun more tightly to form compact cords. It’s ideal for wrapping bakery boxes, hanging plant pots, and bundling small goods.

Jute rope, however, ranges from 6 mm to over 25 mm in diameter. It’s twisted or braided to handle higher tension and is commonly used in shipping, rigging, interior design elements, and large-scale packaging. The flexibility in sizing and strength allows manufacturers to create custom-grade rope depending on end-use needs.

Conclusion

As industries across the globe shift toward sustainable practices, jute twine and rope stand out as practical, biodegradable solutions. Their natural strength, environmental safety, and wide applicability across sectors—from farming and crafts to packaging—make them an ideal alternative to synthetic materials.

With plastic bans and eco-regulations expanding, demand for jute products continues to grow. Exporters equipped with quality control, customization options, and sustainability certifications are seeing strong opportunities in key global markets. For buyers looking to align with the future of sustainable trade, sourcing jute twine and rope is both a strategic and responsible decision.