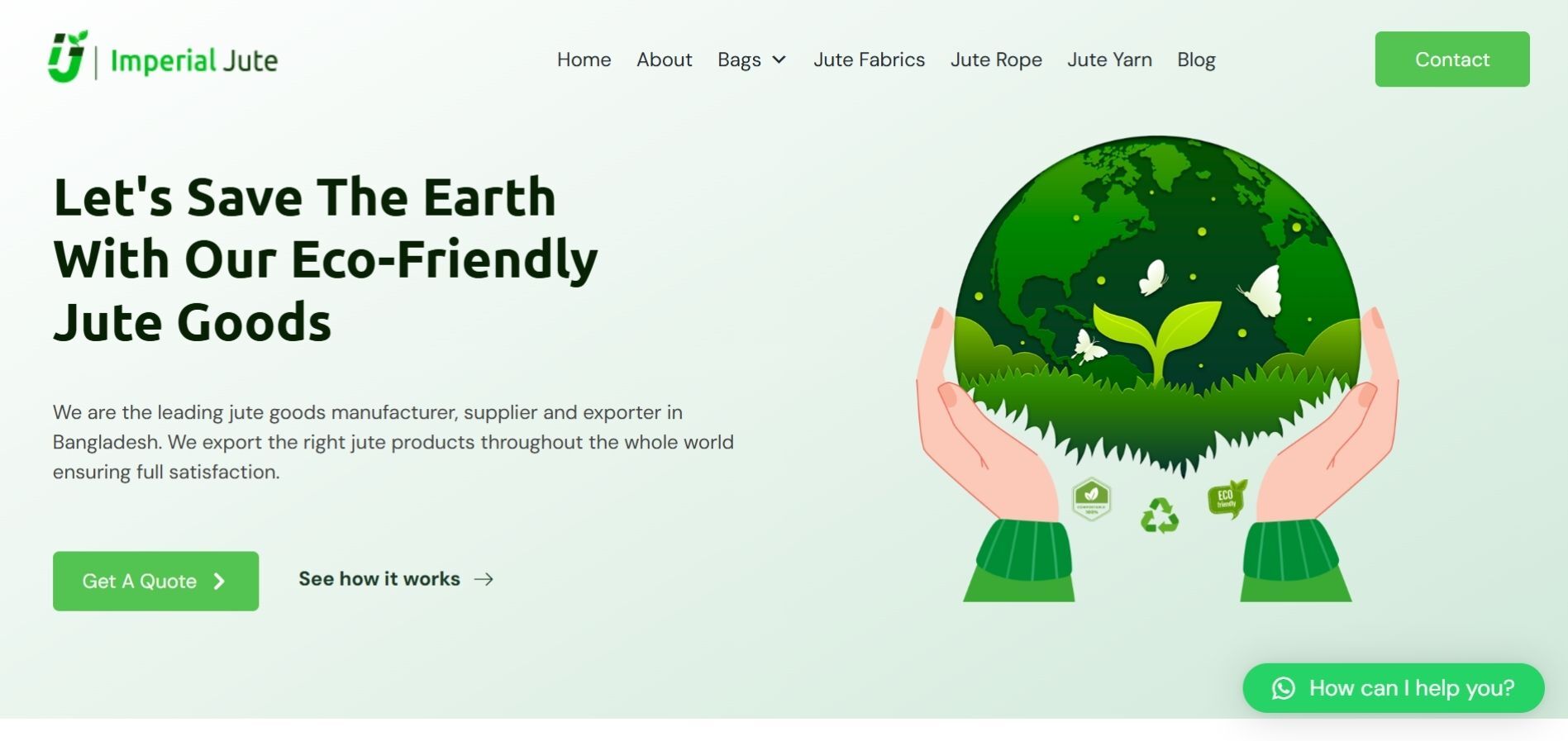

Jute, known worldwide as the “Golden Fiber,” plays an inevitable role in today’s shift toward eco-friendly products. It is a strong, biodegradable, versatile natural fiber, mainly used to create bags, carpets, clothing, ropes, and home décor items.

In this guide, we will break down the complete manufacturing journey of jute, step-by-step, from farming to finished goods. Whether you are a business owner, environmental enthusiast, or simply curious about sustainable materials, this article will guide you to understand how simple jute plants transform into products used worldwide.

1. Cultivation of Jute Plants

Before any manufacturing starts, jute must be cultivated under very specific conditions. The climate, soil, and farming techniques directly influence the strength, length, and shine of the jute fibers.

Where is Jute Grown?

Most of the world’s jute comes from South Asia, particularly Bangladesh and India. Together, these two countries produce about 95% of the global jute supply.

| Country | Global Production Share |

| Bangladesh | 70%+ |

| India | 20%+ |

| Nepal, Myanmar, Thailand | 10% |

Bangladesh is especially known for producing superior golden jute — finer, shinier, and stronger than most other varieties.

Ideal Conditions for Jute Farming

Successful jute cultivation needs:

- Warm temperatures between 24°C and 37°C

- Heavy rainfall of 150–250 cm annually

- High humidity around 80% or more

- Alluvial soil (fertile, water-retentive)

The jute crop is typically sown between March and May and harvested between July and October, depending on rainfall patterns.

Farmers use natural fertilizers and traditional seeding methods to ensure better fiber yield. A healthy jute plant can grow up to 10–12 feet tall in just 120 days.

2. Harvesting

Once the jute plants mature, they need to be harvested at the correct time to ensure fiber quality. Harvesting is a delicate balance because if harvesting is too early, that results in weaker fibers; on the other hand, harvesting too late makes the fiber coarse and hard.

When and How is Jute Harvested?

- Timing: Jute is harvested when the plants are at the early flowering stage but before seeds mature.

This ensures long, soft, shiny fibers. - Method: Farmers cut the plants close to the ground using sharp sickles. Harvested stalks are bundled together and left standing in the fields for 2–3 days to allow excess water to drain out.

- Bundling and Transport: Bundles are then taken to nearby water bodies (ponds, rivers, canals) for the next crucial step: retting.

3. Retting: Separating the Fiber from the Stalk

Retting is the most critical process in jute manufacturing. It is the step where the valuable fibers are loosened from the core of the jute stalk through controlled decomposition.

What is Retting?

Retting refers to submerging jute stalks in water to allow microbial activity to break down the sticky bio-chemical adhesive that binds fibers to the stalk. This process softens the stems so that the fibers can be separated easily without damage.

Without proper retting:

- Fibers become weak or brittle

- Color darkens

- End-product quality drops significantly

Types of Retting Methods

There are four primary methods:

| Method | Process | Pros | Cons |

| Water Retting | Submerging stalks in ponds or rivers | High-quality fiber, traditional method | Requires clean water and environmental impact |

| Mechanical Retting | Using mechanical rollers to crush stalks | Faster process | Fiber strength is often reduced |

| Chemical Retting | Using chemicals or enzymes | Rapid retting | Costly, may damage fibers |

| Microbial Retting | Using bacterial cultures to accelerate retting | Eco-friendly, faster | Still under development, not widely adopted |

How Traditional Water Retting Works (Step-by-Step)

- Bundles of stalks are tied and immersed in slow-moving or stagnant water.

- They are weighted down with logs or stones to keep submerged.

- Retting usually takes 10 to 15 days, depending on temperature and water quality.

- Workers monitor the process daily to prevent over-retting.

Fact: Proper retting improves fiber strength by up to 20–30% compared to rushed or incomplete retting.

4. Stripping and Washing

Once retting is complete, the fiber must be stripped out manually. This step demands a lot of labor, skill, and patience, but it defines the initial quality of jute.

How is Stripping Done?

- Workers grab the stalk at one end, break it, and pull the fiber out in a single motion.

- The extracted fibers are long, shiny, and sticky.

- Fibers are washed multiple times in clean water to remove leftover plant material and dirt.

Drying After Washing

After stripping and washing, jute fibers are sun-dried:

- Fibers are spread out on bamboo poles or grassy fields.

- Sun drying takes 2–3 days, depending on humidity levels.

- Proper drying prevents mold growth and keeps fibers bright and golden.

Pro Tip: Over-drying can make fibers brittle; under-drying can lead to fungus attacks.

5. Grading of Jute Fiber

Not all jute fibers are equal, and grading helps in setting prices and deciding final usage (bags, cloth, ropes, etc.).

How Grading Works

After drying, fibers are classified based on:

- Length (longer = better)

- Color (bright golden preferred)

- Fineness (thinner fibers are premium)

- Strength (tested by pulling)

- Luster (natural shine)

Public and private agencies follow strict grading guidelines.

Common Jute Fiber Grades

| Grade | Description | End Use |

| TD-1 | Best quality, bright golden | Fine fabrics, handicrafts |

| TD-2 – TD-3 | Good quality | Premium bags, hessian cloth |

| TD-4 – TD-6 | Medium quality | Sacks, ropes |

| TD-7 – TD-8 | Lower quality | Rough sacking, industrial material |

Higher grades fetch 40% – 70% higher prices in international markets.

6. Jute Processing in Mills

Once jute fibers are graded and sold, they are transported to jute mills for industrial processing. This part of the journey transforms raw jute into yarn, fabric, or finished products ready for export and use.

Jute mills are large factory complexes where thousands of tons of fiber are processed monthly, especially in countries like Bangladesh and India.

How Mills Prepare Jute Fiber

Raw jute fibers cannot be directly used to make yarn or cloth. They must be softened, carded, drawn, and spun first.

Here’s the whole process:

6.1 Softening and Conditioning

- Softening prepares the jute for mechanical handling.

- Jute fibers are sprayed with water or emulsion oils to make them flexible.

- In traditional methods, workers manually beat the fibers to soften them.

- In modern mills, softener machines are used to crush and lubricate fibers at high speed.

Efficiency Data: A single modern softener machine can process up to 5 tons of jute fibers in 8 hours!

6.2 Carding

- Carding separates and arranges the fibers into a parallel formation.

- It removes entangled clusters and impurities.

- The output is a continuous sheet of aligned fibers called a sliver.

Note: Good carding improves yarn quality significantly by ensuring consistent thickness.

6.3 Drawing

- Drawing is stretching and combining multiple slivers.

- It ensures evenness and strength across the fiber mass.

- Jute passes through 2 or 3 drawing frames to make it ready for spinning.

6.4 Spinning

Spinning turns the drawn slivers into yarn.

- Machines called Spinning Frames twist and bind the fibers together.

- The yarn’s thickness and strength can be adjusted based on end use.

- Fine yarn ➔ shopping bags, handicrafts

- Coarse yarn ➔ sacks, ropes, carpets

| Yarn Type | Uses |

| Fine count (e.g., 8 lb to 12 lb) | Light fabrics, premium bags |

| Coarse count (e.g., 14 lb to 20 lb) | Heavy sacks, ropes |

6.5 Winding and Beaming

- After spinning, yarn is wound onto spools or beams.

- Wound yarns are ready for weaving into fabrics or for direct selling to other industries.

7. Weaving Jute Fabrics

Once the yarn is ready, it is woven into different types of jute fabrics using mechanical looms.

How Jute Weaving Happens

- Warp and weft yarns are arranged perpendicular to each other.

- Mechanical looms weave these yarns into cloth sheets.

| Common Jute Fabrics | Description | Uses |

| Hessian Cloth | Light-weight, fine weave | Shopping bags, decor |

| Sacking Cloth | Heavy-duty, coarse weave | Industrial sacks |

| Canvas | Tight heavy weave | Tents, tarpaulins |

Production Fact: A modern loom can weave 500–700 meters of jute fabric per day!

8. Finishing and Treatments

Raw woven jute fabric is not ready for the market until it undergoes finishing processes. This is where jute gets dyed, laminated, or chemically treated to enhance performance and appearance.

Common Finishing Processes

- Bleaching: Removes natural brown color if a whiter appearance is needed.

- Dyeing: Adds colorful tints for fashion and home décor applications.

- Calendering: Passes fabric through rollers to smooth and gloss the surface.

- Waterproof Coating: A thin layer of laminate or PVC is added to resist moisture.

- Fire Retardant Treatment: Special chemicals make jute fabric safer for indoor use.

Insight: Jute with lamination is now a hot favorite for premium shopping bags and luxury gift packaging.

Challenges in Jute Manufacturing

While jute is one of the most sustainable natural fibers, manufacturing it is not free from demanding challenges. Understanding these problems helps us see why the jute industry sometimes struggles compared to synthetic materials. Some major challenges are discussed below.

1. Seasonal Dependence

- Jute farming depends heavily on rainfall and river water for retting.

- Droughts or floods can destroy entire crops.

- Climate change is making jute farming even riskier.

2. Water Pollution from Retting

- Traditional water retting can pollute ponds and rivers with organic waste.

- This affects drinking water and local biodiversity.

In Bangladesh, studies show retting activities raise Biological Oxygen Demand (BOD) levels in water bodies by more than 400% during harvest season.

3. Labor-Intensive Work

- Stripping, washing, and grading jute still require a lot of manual labor.

- Workers are moving to cities, leaving a labor shortage in jute producing rural areas.

4. Competition from Synthetic Materials

- Cheaper synthetic fibers like polypropylene and polyester often replace jute in industrial packaging.

- Lack of strong marketing and branding has reduced jute’s global image compared to plastics.

5. Price Volatility

- Jute prices can fluctuate heavily based on crop yield, political instability, or currency shifts, making it hard for manufacturers to plan production.

Innovations and Modernization in the Jute Industry

Despite challenges, the jute industry is evolving fast through new technologies and innovative uses. Modernization is helping jute stay competitive in today’s global eco-conscious market. Some key Innovations in recent times are presented here.

1. Improved Retting Methods

- Microbial Retting using selected bacteria strains can complete retting in 4–6 days instead of 15.

- It also reduces water usage by up to 40% compared to traditional methods.

2. Diversified Jute Products

- Beyond bags and sacks, jute is now used for:

- Geo-textiles (for soil erosion control)

- Composites (for automobile interiors)

- Home furnishings (carpets, curtains, wall hangings)

- Biodegradable packaging for food items

3. Jute-Based Technical Textiles

- Jute-reinforced composites are being tested for making car parts, furniture, and building materials.

- Lightweight and eco-friendly alternatives to plastics are driving research.

4. Digitization and Smart Manufacturing

- Modern manufacturing processes use automation for spinning, weaving, and bag stitching.

- ERP systems (Enterprise Resource Planning) are used for inventory and production tracking in large jute mills.

Sustainability and Environmental Impact of Jute

Jute is often called the “Fiber of the Future,” and rightly so. Its environmental benefits far outshine synthetic alternatives.

How Jute Helps the Planet

- Biodegradable: Decomposes naturally within 6 months.

- Carbon Sequestration: 1 hectare of jute plants can absorb about 15 tons of CO₂ and release 11 tons of oxygen during their growth cycle.

- Low Water Footprint: Requires far less water compared to cotton or synthetic fiber crops.

- No Need for Chemical Fertilizers: Grows easily with organic manure.

- Improves Soil Health: Jute cultivation improves soil structure and fertility for future crops.

Future of Jute Manufacturing

The future of jute looks stronger than ever, driven by global trends toward eco-conscious living.

Future Trends and Opportunities

1. Rising Global Demand

- Countries banning plastics (like EU nations, Bangladesh, and India) are rapidly increasing their use of jute alternatives.

- Major retailers are sourcing eco-packaging made from jute for groceries and fashion products.

2. Technological Advancements

- Nano-jute technology is being researched to make lightweight, high-strength fibers.

- Bio-plastic blends combining jute with resins for packaging are under commercial testing.

3. Sustainable Branding

- Eco-conscious brands like IKEA and Patagonia have started introducing jute-based items in their product lines.

4. Government Support

- Governments are introducing subsidies, training programs, and export incentives to promote jute industries, especially in Bangladesh and India.

Market Data: The global jute bag market is projected to grow from USD 2.1 billion in 2023 to USD 3.3 billion by 2028, at a CAGR of 9.5%!

Frequently Asked Questions About the Jute Manufacturing Process

What is the Jute Yarn Manufacturing Process?

The jute yarn manufacturing process is a series of industrial steps used to convert raw jute fibers into strong, durable yarn used in textiles, ropes, bags, and other applications. This process involves cleaning, softening, aligning, and spinning the jute to produce high-quality yarn in various counts and forms.

It starts with the selection of raw jute and continues through steps like batching, softening, carding, drawing, spinning, and winding. Each stage is designed to enhance the fiber’s flexibility, uniformity, and strength, resulting in yarn that’s ready for use in hessian fabric, twine, and other jute-based products.

The entire process ensures the yarn meets quality standards for strength, twist, moisture content, and appearance, making it suitable for both domestic use and international export.

What happens after jute fibers are dried?

Dried jute fibers are transported to mills, where they are sorted, softened, and processed through carding and spinning machines to produce jute yarn or threads.

How is jute yarn turned into fabric?

Jute yarns are woven using looms to create various types of jute fabric like hessian cloth, sacking, or canvas. The final fabric may undergo dyeing, lamination, or other finishing treatments depending on its end use.

Is jute manufacturing eco-friendly?

Yes, jute is one of the most sustainable natural fibers. It is biodegradable, requires no synthetic inputs, and has a low water and carbon footprint throughout its lifecycle.

Which countries are major jute producers?

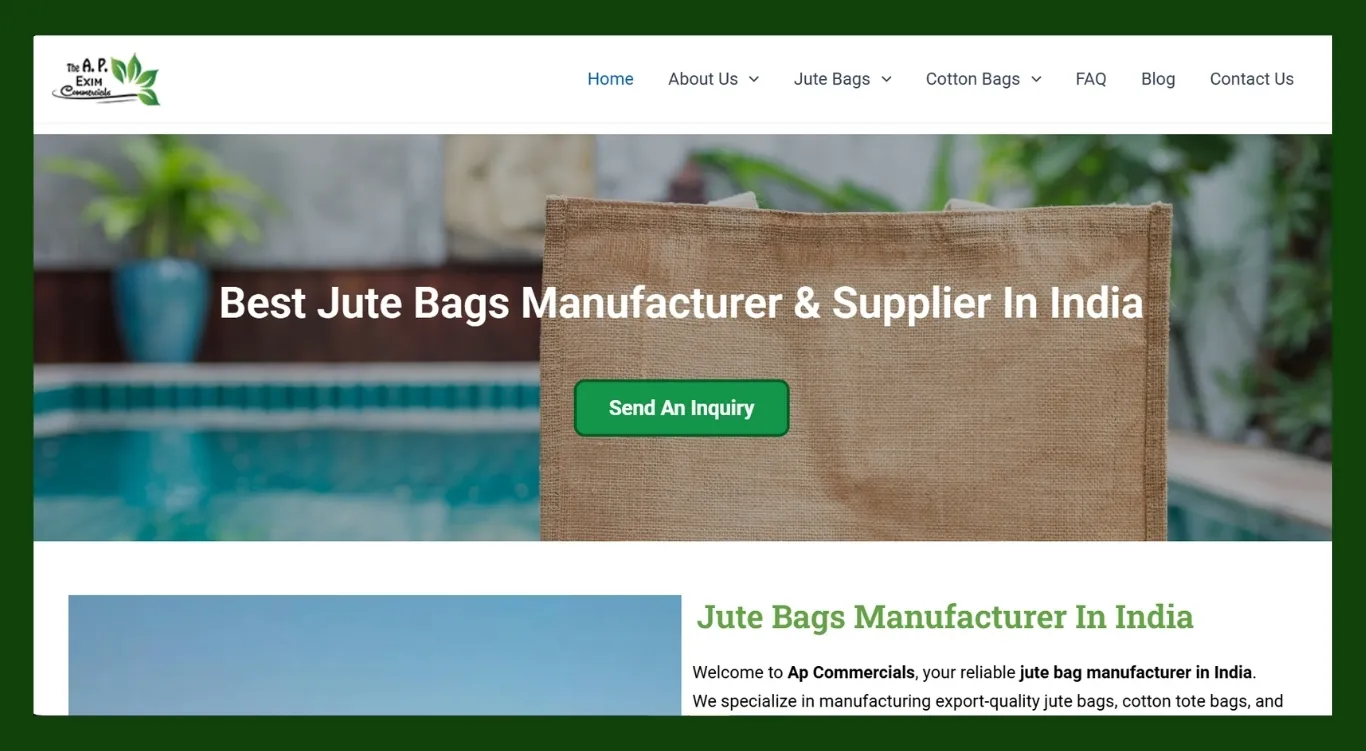

The top jute-producing countries are Bangladesh and India, accounting for over 90% of global production.

What are the common uses of manufactured jute fabric?

Jute fabric is widely used to make bags, sacks, ropes, carpets, geotextiles, home décor items, and eco-friendly packaging solutions.

Can jute processing be automated?

Yes, many jute mills use automated machinery for spinning, weaving, and finishing. However, some steps, such as retting and stripping, are still done manually in traditional farming areas.

Conclusion

From the fertile plains of Bangladesh and India to eco-stores in Europe and America, jute is weaving a story of hope for a greener future. The jute manufacturing process combines ancient techniques and modern innovations from cultivation, retting, stripping, spinning, weaving, and finishing.

Despite challenges, the rise of sustainable living, the banning of plastics, and continuous innovation position jute as a fiber of the future. Whether you are a consumer, a business owner, or a policymaker, investing in and promoting jute today will mean a healthier planet tomorrow.