Hessian fabric bags, also known as burlap or jute sacks, have become an essential part of industrial and agricultural packaging in Algeria. As businesses shift toward sustainable and cost-effective materials, hessian bags have emerged as a reliable solution for bulk storage, export packaging, and agricultural transport.

This article examines the growing presence of hessian fabric bags in the Algerian market, covering their applications across various industries, procurement considerations, differences between fabric and cloth bags, and key factors to consider when importing or sourcing in bulk.

What Are Hessian Fabric and Cloth Bags? A Quick Overview

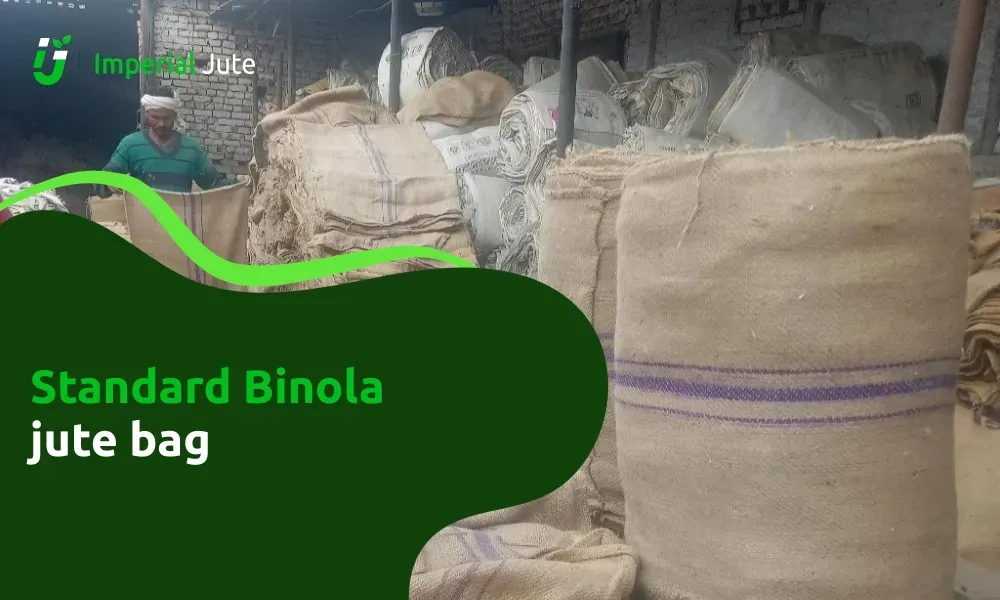

Hessian fabric bags are strong, breathable, and biodegradable sacks made from jute fibres. They are used for packaging and transporting various goods, especially in agriculture, food, and construction industries.

These bags are often confused with cloth bags. While both terms are used interchangeably, they refer to slightly different aspects. “Hessian fabric” emphasises the woven structure and fibre content, whereas “hessian cloth” tends to describe the texture and specific end uses.

Hessian fabric bags offer durability and airflow, making them ideal for perishable goods such as produce, seeds, and grains. Their biodegradability aligns with Algeria’s growing interest in eco-friendly packaging. Due to their coarse texture, hessian cloth is also popular in design and crafts, but bulk buyers often prioritise fabric-based durability over aesthetic finish.

Fabric vs. Cloth – Is There a Difference?

Yes, there is a practical distinction between hessian fabric and cloth bags, especially in procurement and manufacturing.

“Hessian fabric bags” are generally woven from raw or semi-processed jute fibers with a focus on strength, breathability, and load capacity. These are typically used in agricultural or industrial supply chains. On the other hand, “hessian cloth bags” may refer to lighter, more refined jute products with softer textures, often used for packaging artisanal goods or for retail branding.

This difference matters when sourcing. Industrial buyers in Algeria often seek high GSM (grams per square meter) and tighter weave density. Retail-focused buyers, meanwhile, might prioritize finish, printability, and customer experience. Misinterpreting these labels can lead to unsuitable product specs during import or procurement.

Procurement Considerations for Hessian Bags in Algeria

Selecting the right hessian bag depends on several technical specifications. Fabric density, weave type, moisture protection, and branding options all impact the bag’s suitability for different industries.

Understanding these variables helps Algerian importers avoid mismatches between product function and industrial needs.

GSM, Size, and Weave Options

GSM refers to the fabric’s weight and density. Most hessian bags used for bulk packaging in Algeria fall between 275 to 340 GSM. This range supports strength while maintaining flexibility and breathability.

Common sack sizes include 22″x36″, 24″x40″, and 26″x44″, though dimensions can be customized based on payload requirements. Heavier goods like cement or sand need tighter weaving and thicker fabrics, while lighter agricultural items may require more breathable construction.

Plain weave is the most common type used for general packaging. Twill weave, which offers diagonal ribbing, provides more tear resistance and is better for heavier-duty use. The choice of weave impacts durability and is often decided based on the product being stored or shipped.

Laminated vs. Non-Laminated Sacks

Lamination adds a thin plastic layer to the inside of hessian bags, offering moisture resistance and protecting goods from humidity or spoilage. Laminated sacks are commonly used for powdered substances, cement, and food grains.

Non-laminated hessian sacks, in contrast, are preferred for breathable storage, especially in agriculture. They allow for air circulation, reducing mold or moisture build-up. Algerian buyers sourcing sacks for dates, onions, or seed potatoes usually opt for non-laminated options to preserve freshness.

The choice depends entirely on the product and the logistics environment, including whether the goods are stored indoors or exposed to variable weather during transit.

Bulk Order Requirements and Custom Branding

Most international suppliers offering hessian bags require a minimum order quantity (MOQ), often starting at 10,000 units. This ensures cost-efficiency in manufacturing and shipping.

Custom branding is also available. Buyers can request logo printing, colored stitching, or size adjustments. These custom features are especially valuable for exporters or wholesalers looking to maintain brand identity while offering sustainable packaging.

Suppliers in India and Bangladesh—two of the largest jute producers—often provide white-label or private-label services for Algerian buyers, along with packaging in bundles for easy warehousing and distribution.

Importing Hessian Cloth Bags into Algeria: What Buyers Should Know

Importing Hessian bags into Algeria requires a thorough understanding of trade routes, regulations, and supplier reliability. Familiarity with the process can help minimise customs delays and prevent compliance issues.

Leading Export Markets Supplying Algeria

India and Bangladesh dominate the global jute market, accounting for over 90 percent of global exports. Algerian importers typically source from Dhaka, Kolkata, or Chennai, as these cities are hubs for jute manufacturing.

Transit time from South Asia to Algeria ranges from 20 to 35 days, depending on shipping mode and port congestion. Most exporters offer FOB (Free on Board) terms, where the buyer assumes responsibility once goods are loaded onto the vessel. Some offer CIF (Cost, Insurance, Freight) for convenience.

These countries offer access to affordable, high GSM hessian bags with wide customisation and compliance options. Their established export experience also helps minimise shipment risk.

Choosing the Right Supplier: What to Evaluate Before Ordering

Not all hessian bag suppliers offer the same quality, service level, or compliance readiness. Choosing a supplier based solely on price can result in poor product quality, missed deadlines, or compliance issues.

Algerian businesses should perform due diligence before confirming orders.

Quality Audits and Factory Certifications

Trustworthy suppliers often hold certifications like ISO 9001 for quality management or GOTS for organic fiber handling. These certificates indicate adherence to international standards.

Factory audits by third parties such as SGS or Bureau Veritas can also help buyers assess a supplier’s production capacity, labour practices, and quality control systems. Large-scale Algerian importers often request third-party audits as a standard practice before entering annual contracts.

Buyers can also request sample lots for on-site testing to verify GSM, stitching, and weave accuracy.

Conclusion

Hessian fabric bags offer Algerian industries a powerful combination of sustainability, durability, and cost-effectiveness. They meet the growing demand for eco-conscious packaging while serving the practical needs of agriculture, manufacturing, and export logistics.

By understanding the differences between fabric and cloth bags, evaluating supplier standards, and preparing the correct import documentation, buyers can make informed, confident sourcing decisions. As Algeria deepens its commitment to sustainable practices, hessian bags stand out as a dependable bulk packaging solution that aligns with both environmental and economic goals.