Algeria’s demand for large burlap bags continues to grow across agriculture, construction, and export industries. These eco-friendly, durable sacks, typically made from jute or hessian, serve a wide range of bulk storage needs from grains to building materials. Their popularity in Algerian markets is tied to their affordability, reusability, and breathability, which makes them ideal for local climate conditions.

This article provides a comprehensive overview of Algeria’s large burlap bag market, including standard sizing, GSM specifications, sourcing options, supplier selection, customization, and export documentation. For B2B buyers, understanding the differences between domestic and imported options, cost structures, and printing capabilities is critical to making informed procurement decisions.

Common Specifications of Large Burlap Bags (Algeria Market)

| Specification | Details |

|---|---|

| Common Sizes (inches) | 22×36″, 24×40″, 26×44″ |

| Load Capacity | 50kg, 60kg, 100kg |

| Usage by Size | – 22×36″: Pulses, wheat, grains – 24×40″: Dates, legumes – 26×44″: Cement, cocoa, coffee |

| Compliance | Suitable for local use and international shipping |

| Stackability | Depends on weave density and material stiffness |

GSM & Weave Characteristics

| Attribute | Details |

|---|---|

| Standard GSM Range | 220 GSM to 320 GSM |

| Application by GSM | – 220–260 GSM: Short-distance or lighter materials – 280–320 GSM: Heavy-duty, export-ready bags |

| Weave Types | – Open weave: Used for onions, potatoes, produce – Tight weave: Used for coffee, cocoa, fine grains |

| Functional Benefits | – Open weave: Breathability and moisture control – Tight weave: Protection from dust, pests, and damage |

| Stacking Efficiency | Higher with tighter weave and higher GSM |

Laminated vs Non-Laminated Options

Laminated burlap bags are growing in demand, especially in regions with higher humidity or for goods stored long-term. A laminated sack adds a thin plastic coating, which enhances water resistance and prevents material seepage.

Non-laminated versions, however, remain dominant in agriculture due to their breathability and biodegradability. Laminated bags offer better surface finish for branding and ensure higher resistance to odor absorption and mildew, key factors in export compliance.

Key Applications of Large Burlap Sacks in Algerian Markets

Large burlap sacks are essential across Algeria’s primary industries, providing a cost-effective and sustainable solution for packaging and logistics.

They are widely used in agriculture to pack barley, wheat, rice, chickpeas, and lentils. Their breathable nature makes them ideal for storing moisture-sensitive items like dates, which Algeria is among the top 10 global exporters of.

In the construction sector, burlap bags are used for transporting cement, sand, and aggregate materials. Their ability to carry up to 100kg while retaining structural integrity under pressure has made them a standard on Algerian building sites.

They also serve in export packaging for dry goods, such as cocoa and coffee. These products require bags that are not only strong but also compliant with phytosanitary and quality regulations enforced by EU and Middle Eastern trading partners.

Where to Find Reliable Bulk Burlap Bag Suppliers in Algeria

Choosing the right supplier in Algeria means balancing production capacity, quality standards, and export readiness. Businesses should assess both local and international sourcing options based on budget and lead time.

Local Manufacturers vs Importers

Algeria has developed its domestic burlap manufacturing in key zones, including Algiers, Oran, and Blida. These facilities cater to agricultural cooperatives, wholesalers, and government procurement bodies.

Sourcing locally provides faster delivery timelines, easier communication, and fewer import duties. Additionally, local suppliers often support region-specific packaging requirements and environmental standards that importers may overlook.

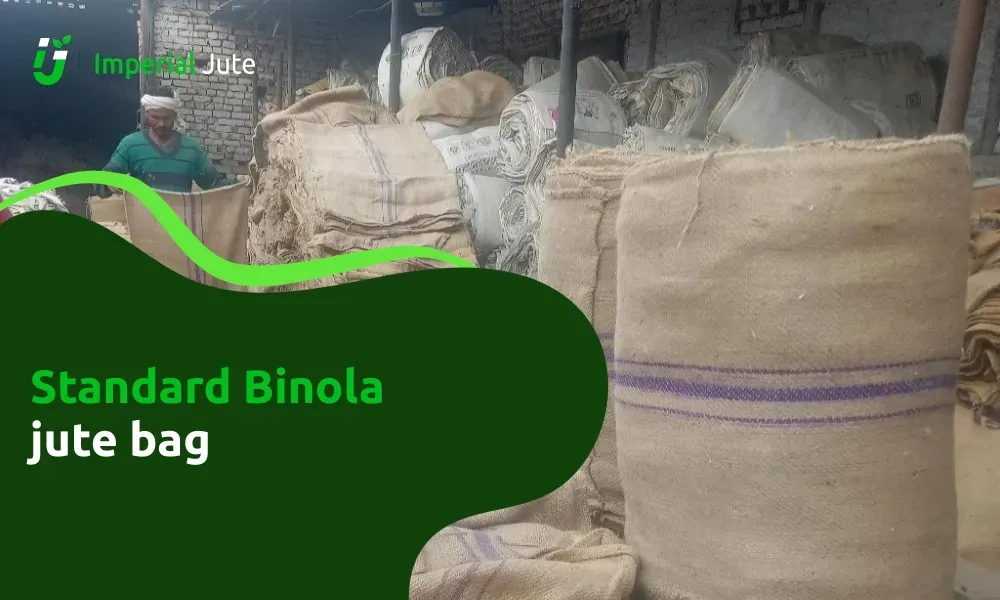

However, importers from India and Bangladesh continue to serve Algeria’s high-volume needs, especially for laminated and printed bags with custom features. They often offer economies of scale but require longer lead times and import clearances.

Top Jute & Burlap Bag Suppliers in Algeria (2025)

Trusted domestic manufacturers in Algeria include mid-sized firms specializing in agro-packaging and textile-grade jute conversion. Several are listed on government-approved tender platforms and B2B directories like Algérie Market and DZExport.

Additionally, B2B marketplaces such as Alibaba and TradeIndia list export-ready suppliers that ship directly to Algerian ports. Always review quality certifications, including ISO 9001, REACH compliance, and recent client testimonials, before placing bulk orders.

How to Order Burlap Bags in Bulk: MOQ, Pricing

Procurement of large burlap bags requires clarity on minimum order quantity (MOQ), pricing structures, and seasonal fluctuations, especially during harvest and export cycles.

MOQ Guidelines for Bulk Orders

Most bulk burlap bag suppliers in Algeria set their MOQ between 10,000 and 50,000 units. This threshold helps maintain efficiency in production runs and keeps per-unit costs competitive.

However, smaller distributors and NGOs can negotiate lower quantities, typically in the 3,000 to 5,000 range at slightly higher unit costs. Trial orders with fewer units are often used to test supplier reliability before committing to larger contracts.

Average Bulk Price per Unit (2025 Rates)

As of 2025, the average price for large unbranded burlap bags in Algeria ranges from $0.26 to $0.42 per unit, depending on size and GSM. Custom-printed sacks cost between $0.45 to $0.70, influenced by ink color, stencil setup, and order volume.

Prices also vary by season. Procurement during Algeria’s post-harvest period (October–December) can attract better rates due to increased production capacity and competitive bidding among suppliers.

Custom Printing and Branding Options on Large Burlap Bags

Algerian exporters and local businesses increasingly use branded burlap bags to enhance product visibility and meet market-specific packaging standards.

Stencil and screen printing remain the most common customization methods. Businesses can choose single-color printing for basic logos or two-color layouts for bilingual labeling (Arabic/French), which aligns with regional distribution needs.

Printing is generally done using eco-friendly, water-based inks that ensure long-lasting results and withstand multiple handling cycles. Print areas are usually centered or side-stamped, depending on brand placement needs.

Custom branding not only boosts market perception but also meets traceability standards in international trade, especially for goods exported to Europe or the Gulf.

Conclusion

Sourcing large burlap bags in Algeria demands a close understanding of local specifications, supplier networks, and trade protocols. From GSM and lamination to bulk pricing and customization, every factor impacts cost and usability.

Whether you’re a domestic distributor, export trader, or logistics firm, this guide offers practical insight to navigate Algeria’s burlap bag industry. Making informed decisions ensures your packaging meets performance needs, budget targets, and evolving sustainability standards.